上海埃飞科技

Worldwide Technology(S. H)上海埃飞科技

Worldwide Technology(S. H)产品展示

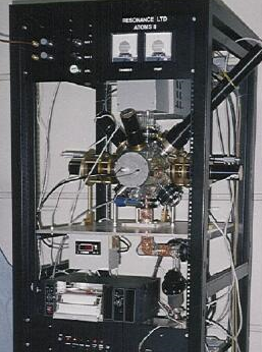

Atomic oxygen exposure system

ATOMS Atomic Oxygen Exposure Measurement System is a material measurement system that simulates low earth orbit conditions, that is, a measurement system that exposes materials to hot atomic oxygen and VUV-UV light.

1. Product introduction:

ATOMS Atomic Oxygen Exposure Measurement System is a material measurement system that simulates low earth orbit conditions, that is, a measurement system that exposes materials to hot atomic oxygen and VUV-UV light. Atomic oxygen is produced by radio frequency separation of oxygen upstream of the exposure chamber. The concentration of atomic oxygen can reach 10^15 atoms/cm through the RFX-500 high-power atomic oxygen generator. This is equivalent to about 2*10^16cm2/s atoms The oxygen flux is equivalent to the 5eV atomic flux measured with the Kapton dosimeter. It is mainly used on the ground to evaluate the changes in material properties caused by the erosion of atomic oxygen and vacuum ultraviolet when aerospace materials are exposed to low earth orbit conditions.

The atomic oxygen density distribution on the material can be measured in situ with an atomic oxygen density profiler based on resonance absorption technology. A beam of 130.2nm atomic oxygen resonance peak directly passes through the exposure chamber, and the beam is exposed to the oxygen atoms in the chamber Absorption, the amount of absorption can be measured by the VUV solar-blind vacuum ultraviolet detector, and the atomic oxygen density distribution on the material can be determined by scanning the optical path.

The system can also simulate the solar spectrum through UV and VUV ultraviolet light sources to evaluate the changes in material performance when the material is exposed to ultraviolet light and atomic oxygen at the same time. The interface of ultraviolet or vacuum ultraviolet light source and atomic oxygen density profiler has strong applicability and can be easily applied to the existing atomic oxygen exposure evaluation system.

2. Product model:

We also provide three complete atomic oxygen exposure evaluation systems to suit different applications and budgets.

• High-profile version of the Atomic Oxygen Exposure Evaluation System

• Standard Edition of Atomic Oxygen Exposure Evaluation System

• Atomic oxygen exposure assessment system budget saving version

The high version and standard version both include atomic oxygen exposure/VUV radiation and atomic oxygen density measurement system.

Configuration options ATOMS-C ATOMS-S ATOMS-SX

Flux> 1015 ph/cm2/s> 5x1015 ph/cm2/s> 2x1016 ph/cm2/s

Oil-free pump

Atomic oxygen exposure chamber

Atomic Oxygen Density Profiler None Include Include

Vacuum UV Simulator None None Included

Separate vacuum ultraviolet-UV light source None Included None

RF separation of oxygen power 90 300 500

Note:

The complete system includes the pump installed on a 47.5cm rack;

The standard system is placed on a shelf with a height of 1.8m;

The budget saving system is installed on a half-high shelf;

In-situ atomic absorption/molecular absorption/fluorescence measurement system;

OAMS and NAMS oxygen absorption and nitrogen atom measurement system;

Profile analysis system, radiance/atomic oxygen density profile analyzer/nitrogen atom density analyzer;

3. Subsystems and options:

Each subsystem can be used as part of a complete system or can be purchased separately.

Atomic Oxygen Exposure Chamber (AO-EC)

Pyrex Vacuum Glass Chamber

A circular sample holder with a diameter of 5cm that can be quickly disassembled;

Intake manifold

Outlet pump valve box with ozone filter and throttle valve;

Additional sample holders/RGA/Atomic Oxygen Density Analyzer/VUV/UV Simulator prepared multiple interfaces;

Vacuum ultraviolet/ultraviolet solar simulator (VUV-UV-SS)

3 vacuum ultraviolet-ultraviolet light sources covering 115-400nm;

3 sets of CF mounting flanges and lamp adapters;

Irradiate the sample with an equivalent solar radiation vacuum ultraviolet-ultraviolet;

Light source includes

Krypton continuous light source (KrCM-L);

Xenon continuous light source (XeCM-L);

Xenon flash source (XeCQ-LF);

Two in-situ measurement modes of in-situ measurement system (measure atomic/molecule density through different methods)

a) Measurement of atoms or molecules based on the principle of absorption;

b) Measurement of atoms or molecules based on the principle of fluorescence;

The type of detection depends on the light source and detector used;

Types of testing include:

Atom: oxygen/nitrogen/chlorine/hydrogen;

Molecule: OH/NO/CO

4. Product Features

a. Simulate low earth orbit: the sample is exposed to a continuous stream of hot atomic oxygen;

b. High flux: Atomic oxygen flux can reach 2*1019cm2/sec (2*1016cm2/sec is equivalent to 5eV atomic oxygen flux measured by Kapton radiometer);

c. Fast measurement cycle: It only takes 1/2 hour to measure the erosion amount of Kapton material, and the typical exposure time is 2 hours;

d. No interference from interfering substances: The sample is downstream of the active plasma and will not be affected by uncontrollable ions/metastable substances/UV radiation in the plasma facility;

e. Solar simulator: Simultaneously use three VUV&UV light sources to simulate solar radiation, which is more realistic and wider;

f. In-situ atomic oxygen density measurement: The atomic oxygen density of the sample can be measured by absorption.

Configuration options ATOMS-C ATOMS-S ATOMS-SX

Flux> 1015 ph/cm2/s> 5x1015 ph/cm2/s> 2x1016 ph/cm2/s

Oil-free pump

Atomic oxygen exposure chamber

Atomic Oxygen Density Profiler None Include Include

Vacuum UV Simulator None None Included

Separate vacuum ultraviolet-UV light source None Included None

RF separation of oxygen power 90 300 500

因用于机器人各方面应用且与大多数机器人类型兼容,AutoCal系统可以检测出机器人自身构造和工具中心点(TCP)的 突然改变或偏离,并且该系统无需人为干涉就自动地更正这些误差。

AutoCal系统-Dynalog的先进水平校准技术,Dynalog是机器人单元标定技术的世界领导者。它的主流产品DynaCal 系统,被应用于离线的机器人单元校准,并作为最精确的和技术先进的机器人校准程序为许多机器人制造商和终端使用者所接受。AutoCal 系统将已证实的DynaCal校准技术结合到一个在线的全自动系统中,该系统专为程序控制和复原而设计的,价格低廉。

AutoCal系统提供在线的机器人校准方案,旨在快速和自动地保证机械设备的工作性能。因用于机器人各方面应用且与大多数机器人类型兼容,AutoCal系统可以检测出机器人自身构造和工具中心点(TCP)的 突然改变或偏离,并且该系统无需人为干涉就自动地更正这些误差。这意味着不用猜测哪里会出错,不用浪费宝贵时间在机器人程序重复校准上,产品品质无任何损失。

AutoCal系统-Dynalog的先进水平校准技术,Dynalog是机器人单元标定技术的世界领导者。它的主流产品DynaCal 系统,被应用于离线的机器人单元校准,并作为最精确的和技术先进的机器人校准程序为许多机器人制造商和终端使用者所接受。AutoCal 系统将已证实的DynaCal校准技术结合到一个在线的全自动系统中,该系统专为程序控制和复原而设计的,价格低廉。