上海埃飞科技

Worldwide Technology(S. H)上海埃飞科技

Worldwide Technology(S. H)产品展示

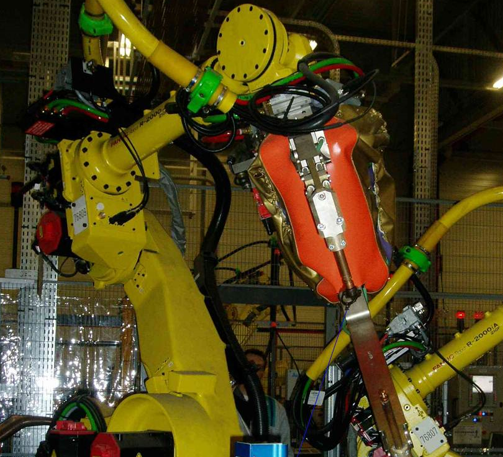

Robot calibration equipment

The DynaCal robot cell calibration system invented by Dynalog changes all of these: it eliminates any differences encountered in the installation of any robot "actually built" and "standard design".

In today's highly competitive global market, manufacturers are increasingly relying on industrial robots to increase the flexibility and adaptability required in the production process. Nevertheless, to make these robots perform their production tasks efficiently and accurately (whether it is spot welding, sealing, arc welding, assembly, water jet cutting, etc.), it takes a lot of time and effort to manually program, which leads to some Loss of flexibility. The solution is DynaCal.

For many years, robots have been manually programmed by specialized technicians. Today, this phenomenon is still common. why? Because, in fact, the robot produced and the installation process will not completely match the design: the manufacturing of each individual robot arm is slightly different; the installation of each end effector (TCP) on the robot is the same as the original design There are some differences; the fixtures on the front of the robot will not be placed exactly where they were designed. For these reasons, automating the robot programming process (offline programming) or modern computer-aided technology, which assumes that the exact same robot cell can be copied, usually becomes ineffective. Therefore, manual trimming is still required.

The DynaCal robot cell calibration system invented by Dynalog changes all of these: it eliminates any differences encountered in the installation of any robot "actually built" and "standard design". The DynaCal solution uses advanced mathematical procedures to first automatically identify any differences in the robot cells (ie robot, TCP, and fixtures) through precise measurements, and then compensate for them. With the DynaCal system, it is possible to design a complete set of automation technology for robots, making the start-up, repair, change and update of new and existing production lines fast And precise

Offline programming: The robot program generated offline by computer simulation can be downloaded to the factory floor without manual trimming. Robot cell clone: A robot program created in a special robot cell can be quickly and accurately cloned to any other duplicate robot cell on the factory floor.

Robot cell movement: The entire robot cell can be moved from one location (integrator's factory) to another location (end customer's factory).

Robot maintenance: Perform preventive robot maintenance to recover from collisions between robots and tools with minimal downtime.

Main purpose: To test the situation where the robot performance is not ideal. This equipment can quickly calibrate the main parameters of the robot and compensate the corresponding correction parameters. For example: robot TCP point, Home point (zero point), connecting rod length, the angle of each axis of the robot, parallelism, load capacity, reduction ratio, coupling ratio, robot base and other parameters. Thereby further improving the performance of the robot.

因用于机器人各方面应用且与大多数机器人类型兼容,AutoCal系统可以检测出机器人自身构造和工具中心点(TCP)的 突然改变或偏离,并且该系统无需人为干涉就自动地更正这些误差。

AutoCal系统-Dynalog的先进水平校准技术,Dynalog是机器人单元标定技术的世界领导者。它的主流产品DynaCal 系统,被应用于离线的机器人单元校准,并作为最精确的和技术先进的机器人校准程序为许多机器人制造商和终端使用者所接受。AutoCal 系统将已证实的DynaCal校准技术结合到一个在线的全自动系统中,该系统专为程序控制和复原而设计的,价格低廉。

AutoCal系统提供在线的机器人校准方案,旨在快速和自动地保证机械设备的工作性能。因用于机器人各方面应用且与大多数机器人类型兼容,AutoCal系统可以检测出机器人自身构造和工具中心点(TCP)的 突然改变或偏离,并且该系统无需人为干涉就自动地更正这些误差。这意味着不用猜测哪里会出错,不用浪费宝贵时间在机器人程序重复校准上,产品品质无任何损失。

AutoCal系统-Dynalog的先进水平校准技术,Dynalog是机器人单元标定技术的世界领导者。它的主流产品DynaCal 系统,被应用于离线的机器人单元校准,并作为最精确的和技术先进的机器人校准程序为许多机器人制造商和终端使用者所接受。AutoCal 系统将已证实的DynaCal校准技术结合到一个在线的全自动系统中,该系统专为程序控制和复原而设计的,价格低廉。