上海埃飞科技

Worldwide Technology(S. H)上海埃飞科技

Worldwide Technology(S. H)产品展示

Cell Artificial Meat

product description: Cell artificial meat was developed in the laboratory by Mark Post, a professor of biology at Maastricht University in the Netherlands, through stem cells, hoping to produce meat through this method of in vitro cultivation of a

Cell artificial meat was developed in the laboratory by Mark Post, a professor of biology at Maastricht University in the Netherlands, through stem cells, hoping to produce meat through this method of in vitro cultivation of animals. Different from plant protein artificial meat, this method is the technical solution closest to the growth and cultivation of natural meat.

Compared with traditional industries, the advantages are as follows

1. The production environment is aseptically sealed throughout the whole process, and is naturally immune to most diseases including mad cow disease. (Prevention of Plague)

2. All raw materials come from common biological laboratories, which greatly helps increase the richness and stability of protein sources at the national social level, and can be regarded as a potential means of food security protection. (Promote safety)

3. The space required for production is much smaller than traditional animal husbandry, which reduces dependence on land and damage to fertility. And environmental damage factors including carbon emissions and antibiotic pollution have become completely controllable. And can continue to optimize. (Shrink the area and reduce emissions)

4. Minimizing animal suffering is the core technology of painless farms. So as to avoid animal protection disputes in international trade (less pain)

5. In a closed environment, the production load is low and the output is stable. It is the future space agriculture-Mars colony, an important basic technology for subsea agriculture.

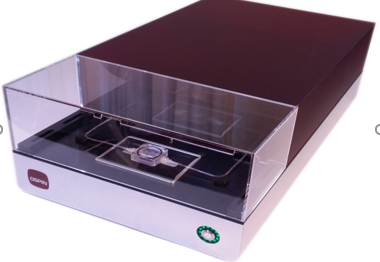

Our company and the German OSPIN company develop a complete set of general biological processing platform solutions, the platform can be divided into two parts:

1- A full set of training programs and operating instructions to help users learn all the necessary knowledge from operation to identification.

2- Complete and modular solution equipment to create customized systems covering a wide range of different applications. Completely build the entire laboratory or optimize existing equipment to add new links.

Through this platform, all users can achieve technological breakthroughs from scratch, even if there is no basis for personnel or experimental equipment before, it can meet the needs of users.

Based on an intuitive user interface, you can design an automated biological process, which can then be executed automatically by the device. OSPIN cloud service allows you to monitor, manage and analyze the bioprocess data generated online.

Technical features:

√ Our platform provides temperature, pH and oxygenation control, glucose feeding, automatic medium exchange, metabolite monitoring and catabolite removal.

√ The biological conditions and processes are reconstructed through electrical and mechanical stimulation.

√ Cloud-based smart tools for bioprocess design, management and analysis can improve and speed up your workflow.

Technical principle:

OSPIN accompanies you from the initial screening stage to the entire process from low workload to medium and large-scale production feasibility. Our equipment is flexible, modular and suitable for any type of application and the type and size of bioreactors. Our platform is usually used in tissue engineering, medical research (such as implants and test systems), stem cell culture, food technology... The culture circulation medium can ensure nutrient supply and can measure process parameters online. The gas exchanger can control the pH and oxygen content in the medium.

Application areas:

Regenerative medicine

Biological 3D printing

Artificial meat

Cell agriculture

Synthetic food

Molecular gastronomy

Future Food

Space agriculture

Tissue Engineering

因用于机器人各方面应用且与大多数机器人类型兼容,AutoCal系统可以检测出机器人自身构造和工具中心点(TCP)的 突然改变或偏离,并且该系统无需人为干涉就自动地更正这些误差。

AutoCal系统-Dynalog的先进水平校准技术,Dynalog是机器人单元标定技术的世界领导者。它的主流产品DynaCal 系统,被应用于离线的机器人单元校准,并作为最精确的和技术先进的机器人校准程序为许多机器人制造商和终端使用者所接受。AutoCal 系统将已证实的DynaCal校准技术结合到一个在线的全自动系统中,该系统专为程序控制和复原而设计的,价格低廉。

AutoCal系统提供在线的机器人校准方案,旨在快速和自动地保证机械设备的工作性能。因用于机器人各方面应用且与大多数机器人类型兼容,AutoCal系统可以检测出机器人自身构造和工具中心点(TCP)的 突然改变或偏离,并且该系统无需人为干涉就自动地更正这些误差。这意味着不用猜测哪里会出错,不用浪费宝贵时间在机器人程序重复校准上,产品品质无任何损失。

AutoCal系统-Dynalog的先进水平校准技术,Dynalog是机器人单元标定技术的世界领导者。它的主流产品DynaCal 系统,被应用于离线的机器人单元校准,并作为最精确的和技术先进的机器人校准程序为许多机器人制造商和终端使用者所接受。AutoCal 系统将已证实的DynaCal校准技术结合到一个在线的全自动系统中,该系统专为程序控制和复原而设计的,价格低廉。